Dynamic checking of page sizes, colour schemes and PDF-X standards.

Who?

aepos.Label target groups are Data-Editors and Data-Processors: digital label printing shops, web offset and sheet-fed offset printing shops as well as prepress.

aepos.Label

The PDF-workflow solution for your automated label printing production

What?

aepos.Label is a 2 in 1 solution particular for label printing: A combination of printorder-management-system and processing planning

How?

aepos.Label includes modules for registering the incoming order, data processing and production planning, color management as well as an automatic transmission of the job to printing and cutting machines.

aepos.Label is a 2 in 1 solution particular for label printing: A combination of printorder-management-system and processing planning with an interface to various shop systems. The software solution optimizes the label printing production.

Transmission of data in the job ticket

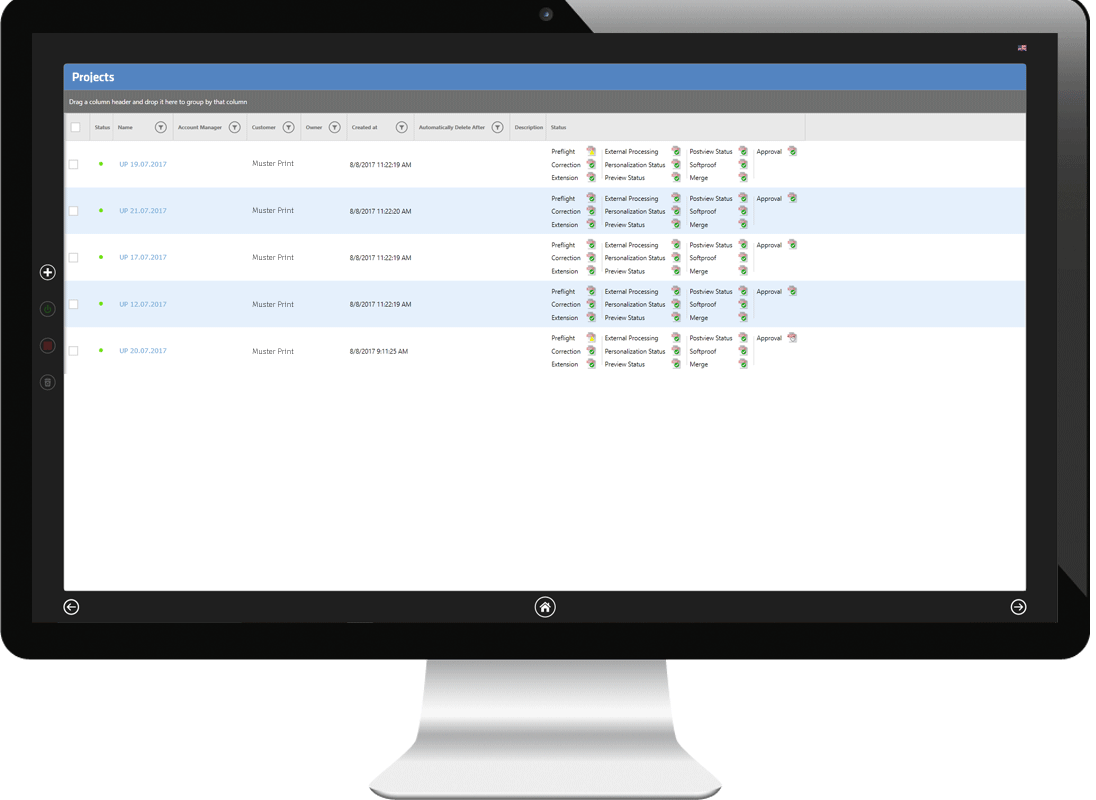

Click on the image to increase it.

aepos.Label includes modules for:

- registering the incoming order

- data processing

- production planning

- a complete color management for carrying out machine-specific color space transformation

- an automatic transmission of the job to printing and cutting machines.

The administration of the job with the corresponding data processing is part of the standard workflow along with the rule-based job summary.

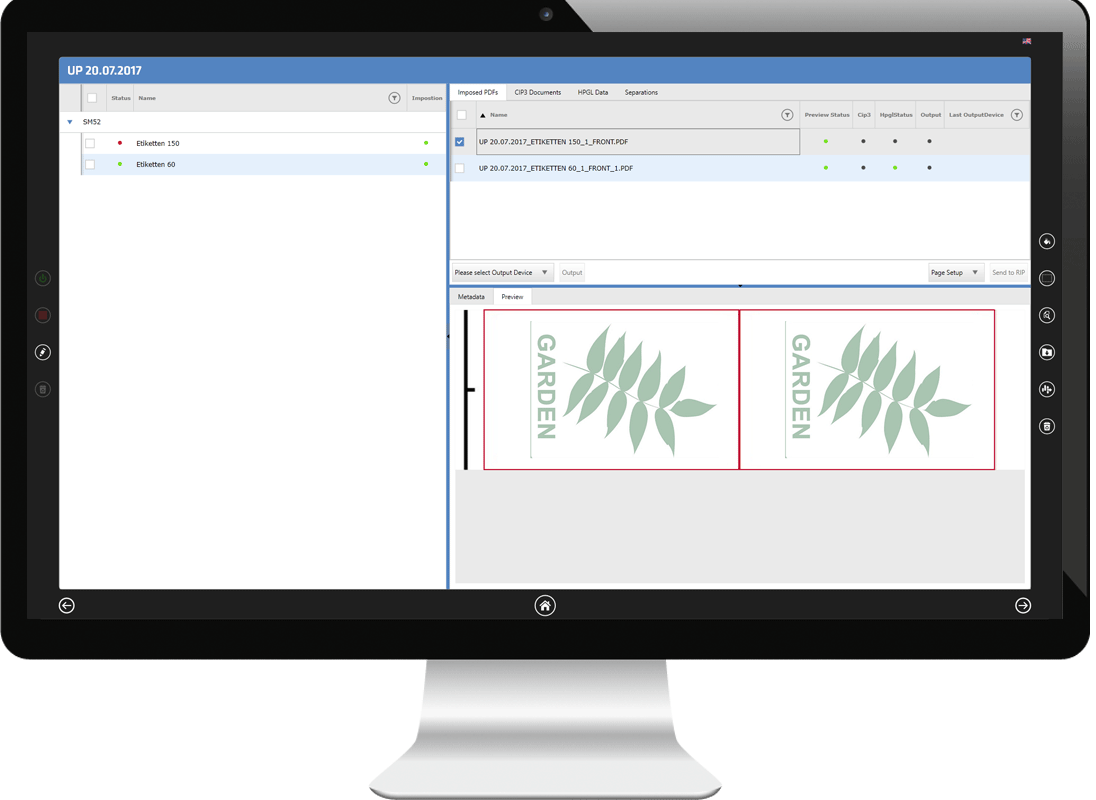

Click on the image to increase it.

order-based process

The order-based approach offers the advantage of complete control. All of the information about a given job is available at all times. This makes processes transparent.

Orders can be generated manually or automatically.

As for the automatic generation Jobtickets or REST-API can be applied.

Thanks to the order-based approach it is possible to make automation processes more individual. This is facilitated by the information about the job.

Click on the image to increase it.

For example:

- paper classes (important for controlling color management)

- specified colour scheme (CMYK/SPOT etc.)

- specified page sizes

- number of pages

This information can be used in order to make processes dynamic.

The job controls the processes.

In correction RGB is converted to CMYK, based on the paper classes. Then come overprinting and normalisation of PDF-boxes. As a supplement there are other configurations available that can be customised to the client.

Here modules are used that are requested for specific jobs. For example, the conversion from Spot to CMYK, from CMYK to CMYK or page scaling.

aepos.Label can if desired automatically generate an overprinted enamel form or an underprinted white form. Here all color elements are used as a basis. The function of the underprinted white is especially helpful in digital production processes with transparent materials.

Personalisation makes it possible to merge PDF-files. Based on job-lists (EXCEL, CSV, JSON), it is possible to place PDFs in other PDFs (change of languages, imprints).

A lined-out preview is rendered from the incoming PDF-data. These data are then also used for calculating the area coverage (ink use).

A lined-out preview is rendered from the prepared PDF-data. This serves as the basis for online-release.

An online-approval-system is provided that can be used via „page linking“ (based on the Softproof-Data) in-house or via e-mail. There is the option of downloading these data as a PDF.

By means of an internal imposition engine (template-based) print forms can be generated as pdf files.

Multiple products from different jobs can be combined in one or more print products.

If a product is linked with a print product, updates are completed automatically (correction-pages are uploaded). Of course this applies to all linked print products.

The automatic generation of cutting data is based on the geometric information of the product. aepos.Label generates standardized cutting information insofar as no cutting data are available. The software draws the cutting line itself and applies it as a special color. Based on this information the system generates the necessary cutting files.

The transmission of the printing job to diverse printout machines occurs by PDF or the combination of JDF and PDF by way of an online clearance system.

Click on the image to increase it.

aepos.Label automatically generates a start page and an end page for every job. These serve as “digital separator sheets” and allow for easy sorting during production with many jobs. The start and end pages contain diverse information among other things on the number of copies, the production data and/or the time as well as control information for further processing. The information can be given out in the form of QR-codes or bar codes for use by other machines or as readable text fields.

aepos. solutions are delivered as Hyper-V Images. The images contain the entire ready-to-run solution with the necessary operating system.

For the images to be useable the client must provide hardware capable of running it. The following system requirements must be met:

1 x Hyper-V based Host with 8 Cores

32 GB RAM

2 X 1GBit Netzwerk Card

2 x 256 GB System Disk (SSD) mirrored

1 TB Data Disc HDD

Field

Digital web printing of labels

Challenge

Mail Druck + Medien has several shop systems and among other things laser cutting machines for processing adhesive label rolls. These enable a digital cutting without the use of cost-intensive sheets. Ideally digital control data are needed for this. The challenge is the automated transfer of the order data to the production processes of the laser cutters.

Implementation

With aepos.Label an automated transfer of the order data gained in the shop to the digital printing and laser cutters is possible. The workflow recognizes cutting data and prepares this information automatically for the laser cutter. For every job æpos.Label automatically generates a start and end page. These serve as “digital separator sheets” and make simple sorting possible for productions with many different jobs. Moreover the start and end pages contain a QR code with diverse information for example on the number of copies, the production date and the cutting information for further processing.

Highlights

| USER-FRIENDLY | ||

| TIME-SAVING |

||

| COST-REDUCING |

||

| RELIABLE | ||

| HIGH QUALITY JOBS |

||

| COMPATIBLE |